Surface Treatment and Passivation

PASSIVATION

• ASTM-A967 — Chemical passivation treatment of stainless steel parts

• ASTM-A380 — Cleaning, descaling, and passivation of stainless steel parts

• ASTM-B912 — Electrical Chemical passivation of stainless steel

• AMS-2700E — Aerospace specifications

• AMS QQ-P-35 — Nitric or Citric methods

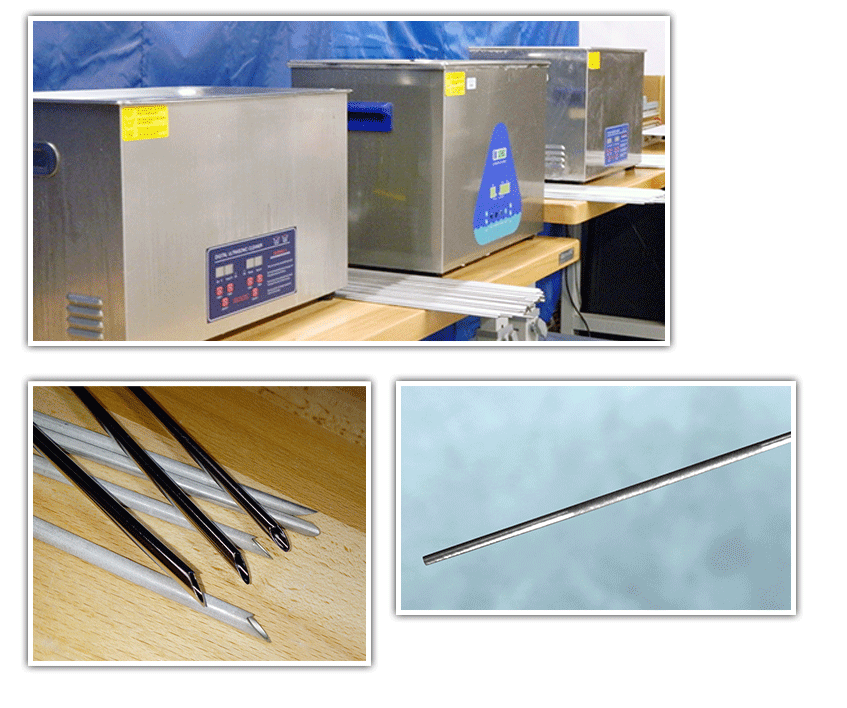

ELECTROPOLISHING

• Finish razor edged tube

• Cleaning prior to passivation

• Surface finish less than 8 RMS

• Ultra sharp pointing of wire

• Bright, shiny finish

PRECISE MICRO-ABRASION

• Preparation for overmolding

• Visual location marking

• Improved finish for adhesion

• Surface finish from 30–320 Ra

• Very tight tolerances held on location

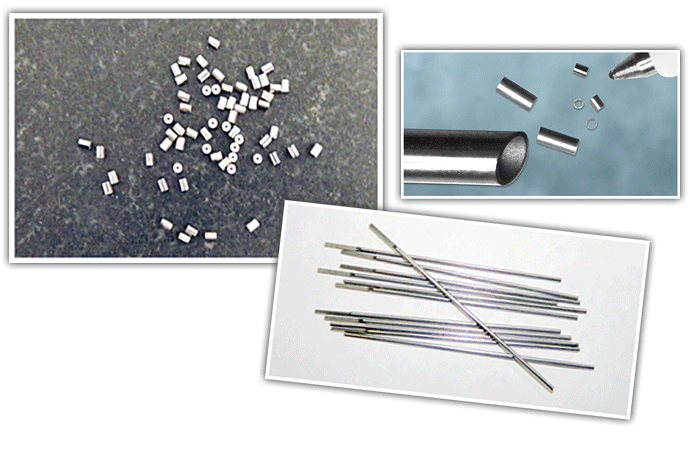

Burr-Free Cutting

Truly burr-free cuts are accomplished by the use of Electrical Discharge Machining (EDM). This process draws a spark from an anode to a part mounted to the cathode. In this way, the material of a wire or tube part is not cut away, but rather turned into a gas much like a plasma cutter but with great precision and repeatability.

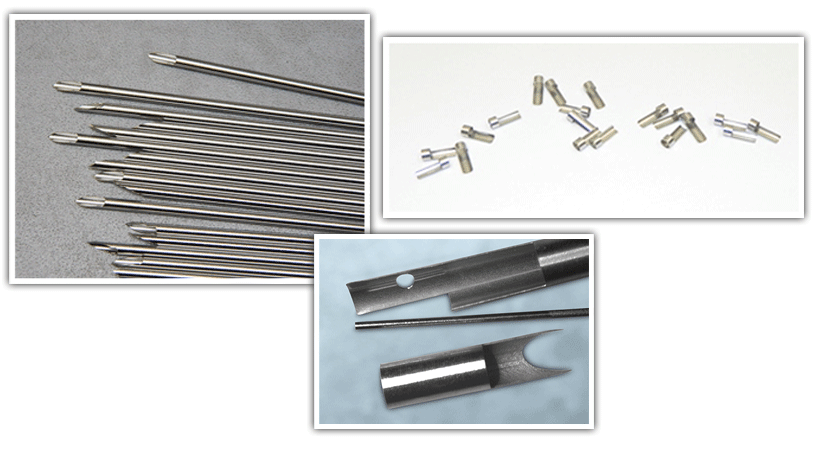

PARTS CAN BE CUT TO VARIOUS SHAPES

• Straight, square ends, rounded ends and angled cuts.

TUBE OR WIRE CAN BE CUT TO EXACTING LENGTHS

• As little as .010” and as long as 10′ with a unique profile with repeatable accuracy of as little as .002”.

Unique profiles are easily cut into tubes of stainless steel, aluminum or any conductive material. Common uses for the process are medical devices and surgical tools, fiber optics, fluid transition or flushing coring devices, applicator needles, vascular introduction cannula, crimping sleeves, machine tools, biorobotics, operating room tools, biopsy stylets and cannulas, and automated system components.

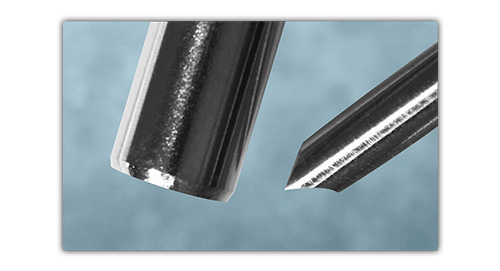

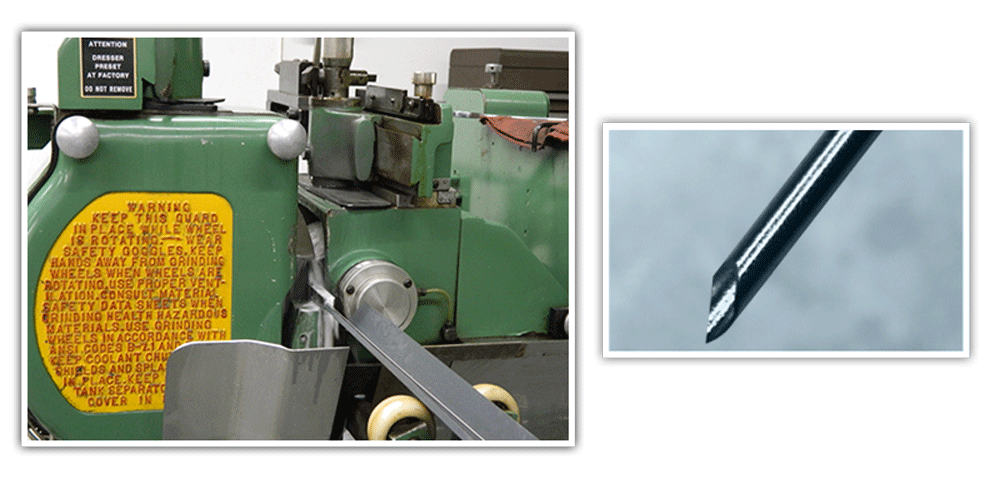

Razor Edged Tubing

• Precision grinding of both inside and outside diameter of tubing up to 0.375”.

• Specialized grinders cut almost any angle on tube diameters producing razor-sharp ends.

• Grinding, combined with cyclical electropolishing creates a smooth finish.

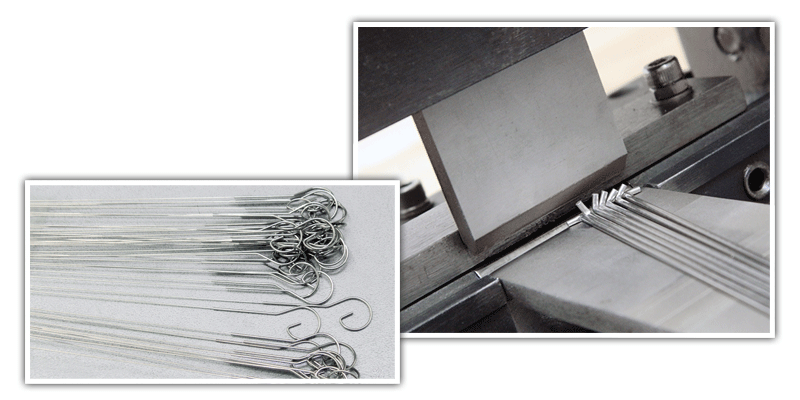

Tube and Wire Forming

• Truly burr-free cuts are accomplished using Electrical Discharge Machining.

• Precision bending of any material, specializing in stainless steel HypoTube of all sizes.

• Swaging of ends or in exact locations along the part.

• Flaring to tight tolerances of tube, all sizes and lengths.

• End closing from full radius to square ends.

• Special shapes of any type per your specifications.

Micro-Precise Grinding

• Micro-precise grinds on wire or tube of any size.

• Centerless grinding with tolerances to +/- 0.0002.

• Tapers up to 3.50” long in multiple, precise locations.

• Steps or notches for overmolding or visible location.

• Flats for locating or clocking to other features.

Micro-Tube Machining

• Slots running longitudinally or radially along tubes or wires.

• Holes down to 0.002” precisely located on the part.

• Features of any kind made to your print.