BURR-FREE CUTTING

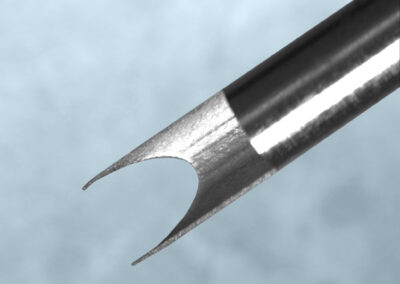

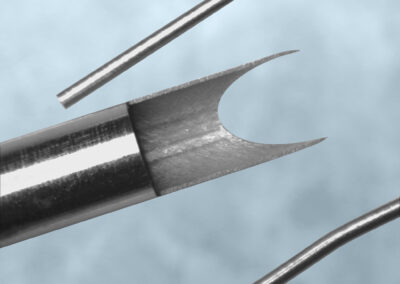

Precision burr-free cuts are accomplished by the use of Electrical Discharge Machining (EDM). This process draws a spark from an anode to a part mounted to the cathode. In this way, the material of a wire or tube part is not cut away but rather turned into a gas much like a plasma cutter but with great precision and repeatability.

- PARTS CAN BE CUT TO VARIOUS SHAPES:

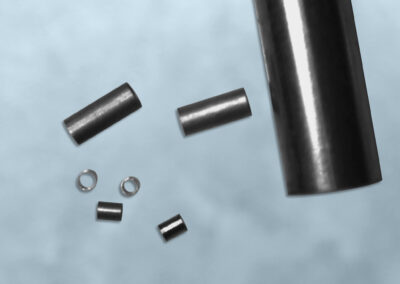

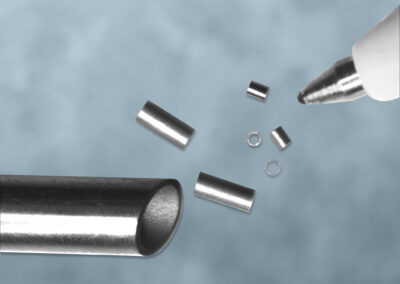

Straight, square ends, Rounded ends and Angled cuts - TUBE OR WIRE CAN BE CUT TO EXACTING LENGTHS:

as little as .010″ and as long as 10′ with a unique profile with repeatable accuracy of as little as .002″

Unique profiles are easily cut into tubes of stainless steel, aluminum or any conductive material. Common uses for burr-free cutting are medical devices and surgical tools, fiber optics, fluid transition or flushing coring devices, applicator needles, vascular introduction cannula, crimping sleeves, machine tools, bio-robotics, operating room tools, biopsy stylets and cannulas, and automated system components.

We are proud to have been certified as an ISO 9001-2015 business in August 2022